Separators

Discover the Power of Precision Engineering in Fluid Separation

Power Service, A DNOW Company, through DNOW U.S. Process Solutions, is redefining the standards of fluid separation technology. Our comprehensive range of separators, encompassing both horizontal and vertical separation systems, is engineered to deliver unparalleled performance. Whether you're dealing with complex process streams involving liquid, gas, or sand, our separators are designed to excel in every scenario.

Product Information

Overview

Maximize oil and gas processing efficiency with DNOW U.S. Process Solutions' advanced separators. Our meticulously engineered systems are at the forefront of technology, offering superior separation solutions for the oil and gas industry. With our products, you’re not just buying a separator but investing in innovation that stands out in efficiency, reliability, and adaptability.

Our separators are not one-size-fits-all. They are specifically designed to cater to various industry requirements, ensuring that our systems provide the most effective separation no matter your process stream’s composition – be it liquid, gas, or sand. This versatility makes our separators preferred for industry professionals seeking solutions that can adapt to different operational needs.

Products Offered

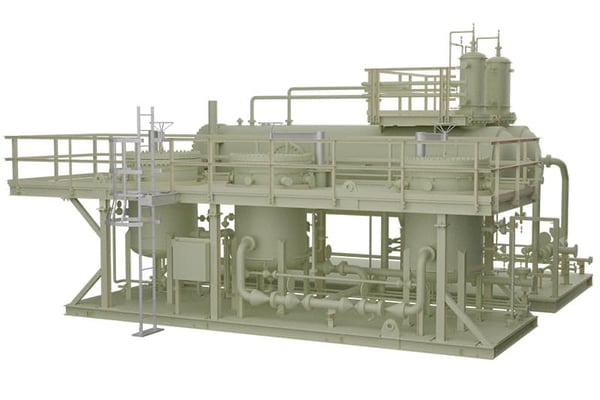

Our designs and construction standards ensure optimum performance for virtually any application.

- Vertical and horizontal separators

- 2-phase, 3-phase and 4-phase separators

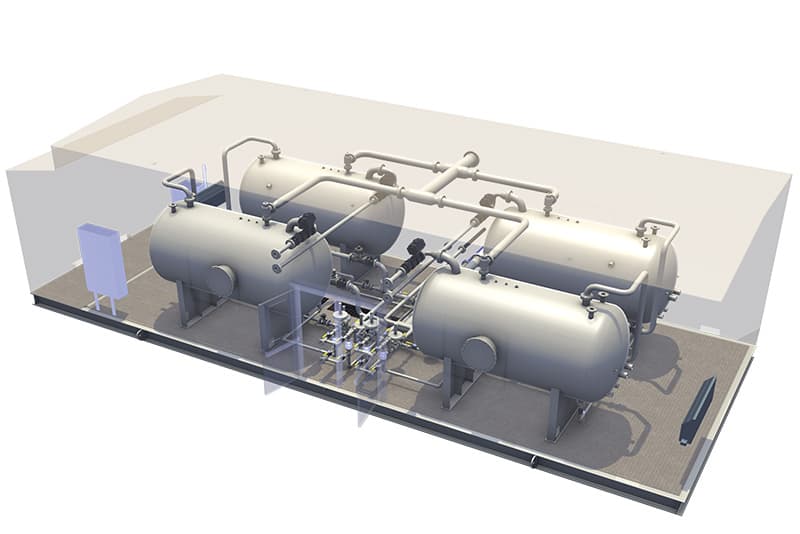

- Modular, skid-mounted test separators

- Hybrid separators (separator + treater)

- Filter separators

- Vertical induced-gas flotation (IGF) cells

- Induced-gas coalescing (IGC) units

- Gas scrubbers

- Free water knockout (FWKO) vessels

- Desanders

- Separator and measurement packages

Features and Benefits

- Optimum Performance: Each separator is designed for peak efficiency in separating different phases in fluid streams.

- Customizable Designs: Modular and skid-mounted options offer flexibility for various operational conditions.

- Innovative Technologies: Hybrid systems combine separation and treatment processes for improved results.

- High-Purity Outputs: Filter separators and gas scrubbers ensure the removal of contaminants and impurities.

- Diverse Applications: From small to large scale operations, our range caters to all types of industrial needs.

- Precision Engineering: Each unit is crafted with meticulous attention to detail, ensuring reliable and consistent performance.

Specifications

| Materials of Construction | Carbon steel, stainless & alloy steel |

|---|---|

| Dimensions | Vessels up to 12 ft. diameter, 100 ft. length, 8 in. wall thickness |

| Lifting Capabilities | Up to 100 tons |

| Non-Destructive Testing | Ultrasonic, hydrostatic, radiographic, dye penetrant inspection, positive material identification (PMI), hardness and others |

| Finishing | Surface prep, blasting, internal and external coating, painting |

| Engineering Support | Design, process simulation, finite element analysis (FEA) |

Certifications

ABSA

ASME U Stamp

CE

CSA

CWB

NB

NBCA R Stamp

UL

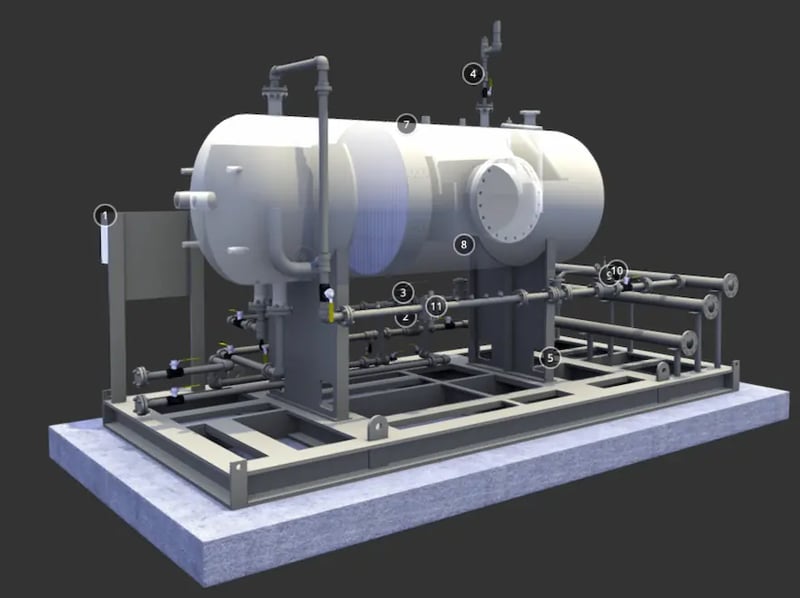

2 and 3 Phase Separator Configurations

Separators come in various configurations to handle different separation tasks and process requirements. This guide will help you understand the key features you can customize for optimal separation efficiency.

Separation Styles:

- Phase/Separation: Select the number of phases your separator needs to handle: 2-phase (gas & liquid) or 3-phase (gas, oil & water).

- Vessel Orientation: Choose between horizontal or vertical separators based on space constraints and process flow.

- Class Rating: Select a pressure rating (150#, 300#, or 600#) that meets your application's pressure requirements.

- Vessel Size: Specify the separator's desired outside diameter and seam-to-seam length.

- Separation Style: There are three main internal configurations to enhance separation: Weir, Bucket & Weir, and Split Heads. Each offers advantages for specific separation challenges.

Additional Options:

- Vessel Accessories: Enhance separation performance with accessories like Inlet Diverters, Baffles, Vortex Breakers, Boots, and more.

- Vessel Coating: Protect your separator from corrosion with external, internal, or internal and external coatings.

- Hydro of Vessel & Pipe: Ensure your separator meets ASME code pressure requirements.

- Packaged Options: You can choose between a bare vessel and a packaged option that includes a basic pneumatic or electric trim package.

Instrumentation & Flow Measurement:

- Gas Line Transmitter: Monitor gas pressure or temperature with a Rosemount transmitter or pressure/temperature combination.

- Oil & Water Line Transmitters (For 2-Phase Separators): Monitor oil or water temperature with optional Rosemount transmitters. (Note: Not applicable for 3-phase separators)

- Gas Metering: Select from orifice plates or meter tubes for gas flow measurement.

- Coriolis Meter (Oil Metering): Opt for a Coriolis meter for accurate oil flow measurement.

- Water Metering: Choose a Micro Motion meter for water flow measurement.

Skid Option:

- Include a steel skid with a deck plate to provide a stable platform for your separator, simplifying installation.

Remember: This is a general overview. For specific sizing and selection guidance, consult with a separator expert.

Simplify Your Complex Ordering Process. Try eSpec™ Today!

Tired of the hassle of configuring and ordering complex engineered equipment? eSpec™, powered by DigitalNOW®, is the solution you've been waiting for. Our online product configurator makes it easy to:

- Customize equipment to your exact needs with a wide range of options and materials.

- See your project come to life with a real-time 3D model.

- Get instant price estimates before you submit your order.

- Save your designs for easy re-ordering and future projects.

Build from anywhere, anytime with eSpec's web-based platform or our convenient mobile app.