- Products & Services

- Process & Production Equipment

- Pressure Vessels

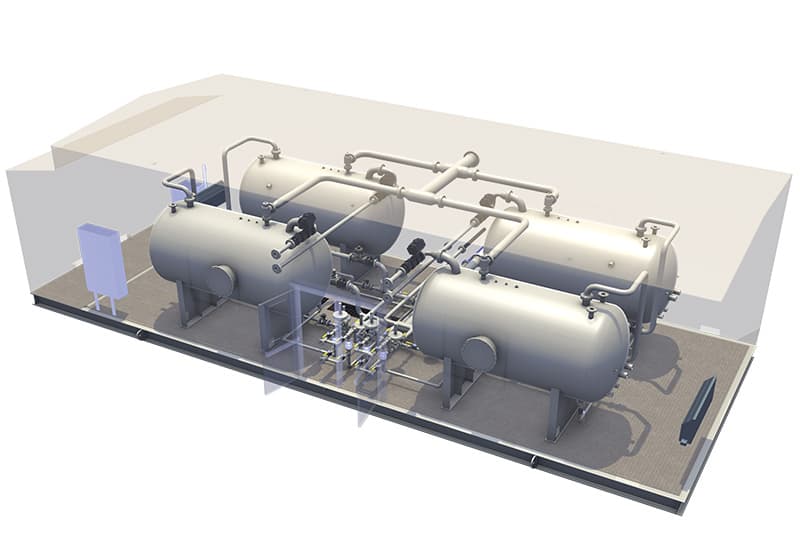

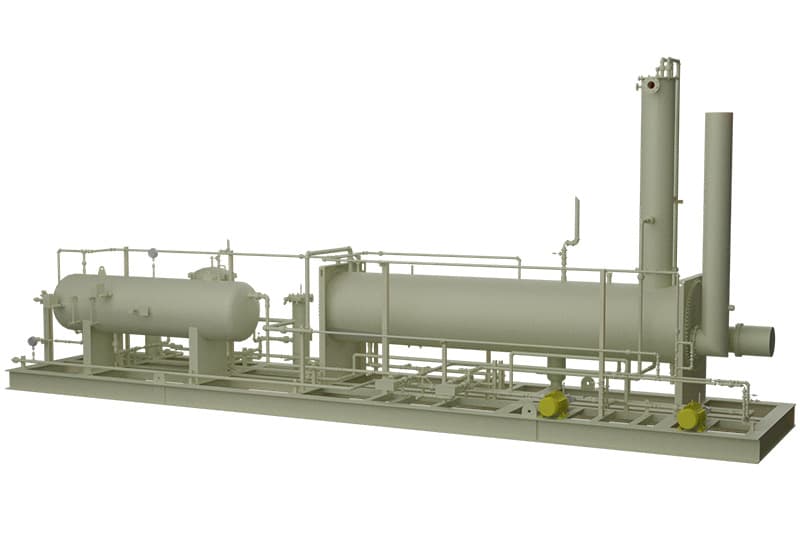

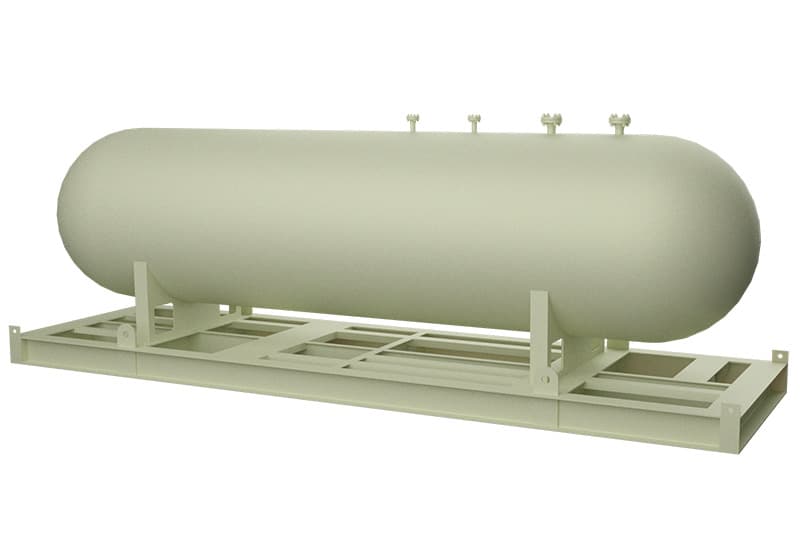

Pressure Vessels

Power Service, Inc., a DNOW Company, engineers and fabricates custom pressure vessels for customers in the oil & gas, energy, water treatment and power generation industries. Our experienced team is known for meeting demanding schedules and quality requirements, and we are able to produce heavy-wall vessels up to 8 inches thick.

Certifications

Every pressure vessel that Power Service, Inc. designs is built to the ASME Boiler and Pressure Code for Design, Section VIII standard. All materials used meet the requirements of the ASME Boiler and Pressure Vessel Code for Materials, Section II standard. Copies of the Power Service, Inc. certifications are available below.

- ASME Pressure Vessels, Section VIII, Division 1 - "U" Stamp – operating at pressures exceeding 15 psig, internal or external, ASME has different requirements for numerous classes of materials as well as for fabrication methods, including welding and brazing

- National Board Certificate of Authorization - "R" Symbol Stamp – repair and/or alteration of boilers, pressure vessels and other pressure-retaining items

Testing & Inspection

Our engineers work closely with our expert drafters to ensure that every pressure vessel that Power Service, Inc. produces meets industry codes and complies with regulations. If no custom testing has been requested by the customer, a third-party certified inspector verifies the product's overall integrity with non-destructive testing (NDT), applies a national board (NB) label and registers the vessel with the National Board of Boiler and Steel Pressure Vessel Inspectors prior to shipping.

Browse Products & Services

Visit Our Resource Center

Access a wealth of assets, from instructional videos to catalogs to white papers, where you'll find product insight and advice on process and production equipment, as well as many other products, services, solutions and supply-chain topics.